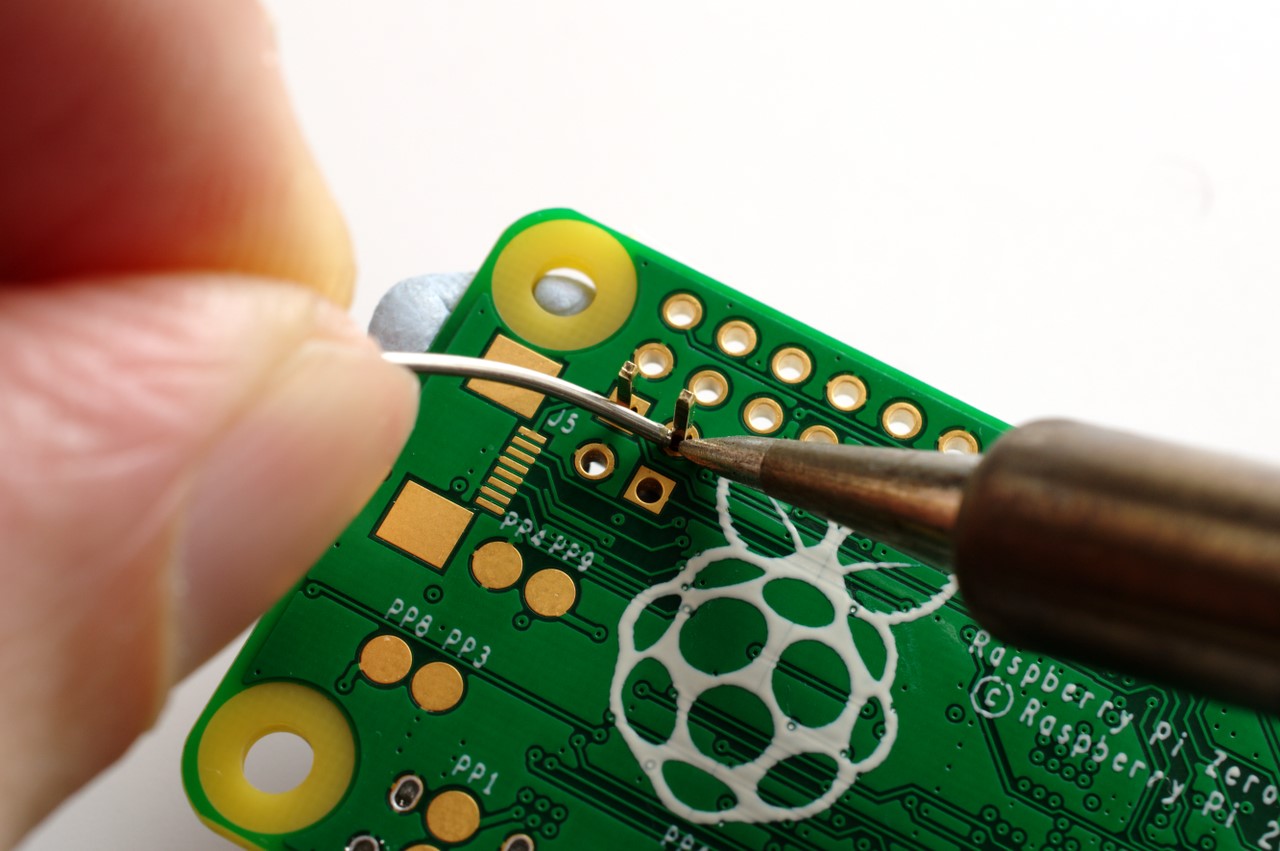

Soldering. (Gareth Halfacree/Wikipedia Commons)

Finally starting to get to the point where I have the resources to start some of my electronic projects (DIY electronics is not a particularly cheap hobby...), so I figured I'd start getting to covering the fundamentals of electronics!

When it comes to soldering irons, it's a question I get often enough that I feel it's nice to have a simple guide to refer people to as they have questions. This guide is definitely intended for people who might not have soldered before, but there might be some useful content for people who have some specific questions as well.

Soldering iron technology hasn't really changed much over the past few decades but I'll consider this a living and breathing webpage so I'll update as I see fit in the future.

I suppose a good place to start is, what exactly is soldering? For someone who's done it their whole life, it's a practice that becomes second nature but ask a random person on the street and they'll most likely have no idea what 'soldering' is.

Essentially all soldering is, is melting a material called 'solder', a pliable metal material, to form bond between two items. These two items could be any combination of wires, or any electrical components such as resistors, transistors, batteries, etc. At the core it, a 'soldering joint' is simply a physical connection between objects that allows electricity to flow through it.

Solder is essentially a pliable metal wire that has a relatively low melting point that you can use to connect electronic components. There's a surprising amount of science behind different types of solder but finding good solder to use is relatively simple and there are really only a couple of things you need to consider.

The first thing to consider is the type of material of the solder - for all intents and purposes, all you have to look at is leaded solder vs lead-free. Lead solder definitely works better but there is always an annoying amount of hoopla about leaded solder because it is, lead. Some applications have banned the use of lead solder (like plumbing) but it is easier to work with so I use it when I can.

The second main thing to consider with solder is the diameter of the solder. For most types of projects, a diameter of around 0.030" is a good thickness to use and gives you enough solder to work with. For more specialized projects, you might need thinner or thicker solder. If you were doing SMT soldering for example (essentially, miniaturized components with pins very close together), you might want to opt for something more like 0.020".

The soldering iron is the tool that is used to heat up solder to it's melting point so that it can be used to connect two things. I'll cover soldering irons in more detail at the end of this guide.

Solder removal - sometimes you make a mistake when you're soldering but fear not! Even though the solder may have solidified, it's usually easy enough to fix soldering mistakes. Most of the time, it's as simple as reapplying the soldering iron to heat up the solder enough to correct your mistake.

With more serious mistakes, a separate tool might be necessary. Soldering wicks are one way to remove solder but I actually find these a pain to use. My favorite way to remove solder is with solder pump. To use a pump, simply heat up the joint using a soldering and then suck out the solder using the pump.

Company longevity - if you're investing in a nice and expensive soldering iron, you definitely want to make sure the company has been making irons for awhile (so you can rest easy getting replacement parts, new tips, etc. down the road). Having a really nice soldering iron but not being able to find parts is not a good predicament to be in. Luckily, there aren't too many companies that have making soldering irons for decades. Edsyn and Weller are two good companies to consider that have been around the block for awhile.

Tips - soldering iron tips do not last forever and need to be replaced every few years so this kinda goes in hand with the first point since a company needs to be alive to make replacement tips. But this is important to consider even as an aside from getting replacement parts because you want to make sure that you can get a good tip for the application(s) you want to use the iron for (as there are many types of soldering iron tips).

Wattage - not something you generally have to worry about since most irons have ample wattage but quite obviously, more wattage equal more power (which, some people might need more than others).

Temperature control - this is essentially one of the main distinguishing factors between a nice soldering iron and a cheap soldering iron. Nice soldering irons can dial to an exact temperature (which is really nice because you often have to fidget with the temperature to get the best results for a particular situation/type of solder). Cheap soldering irons usually only have two modes: off and blazing hot, which is definitely not ideal for some situations.

Temperature readout - this isn't really too important in my book but some irons come with LED temperature readouts so you know exactly what the iron temperature is at any time (but therefore, has more components that can break over time). Some irons only come with a temperature dial (that you use to set a temperature but as such, the dial doesn't necessarily equate to what the iron is at that exact moment in time).

It's honestly probably not worth it to spend too much time on cheap soldering irons because they're are all roughly the same but if you're looking for the cheap solution (either because money is tight, you're not sure how much soldering you'll actually do, or maybe you're not sure you'll need a soldering iron that will last you decades), there's nothing wrong with getting a cheap soldering iron!

You should easily be able to get by for around ~$20 if you want something that will get the job done for cheap. I think the following iron is a decent deal and covers the basics.

If you're looking for an iron that might last you decades and will be a little bit easier to use, expect to drop about ~$100+ for a good soldering iron (though you really can set the price for a nice iron - they come in so many configurations).

A good place to start might be either Weller or Edysn. My family has used both companies irons over the past few decades and they've both held up to be fairly reliable (I use the Edsyn 951SX and I like it a lot).

At the core of it, soldering is pretty simple and really one just has to practice soldering to become a master of it. I do realize that it's a little intimidating at first though so I'm attaching a couple of tutorial videos here in case you haven't soldered before.

I hope this guide covered the fundamentals and answered any questions you might have about soldering. Of course, if you have questions, feel free to leave it in the comments below!

Ukulele strummer, milk enthusiast, and sushi connoisseur. Was the leading scorer on my amateur soccer team last season. I'm also a true nerd at heart and an aspiring rocket scientist.

Comments